-

Parameters

-

Comments

| AL2O3 % ≥: | 70-85 | SiO2 % ≤: | 13-26 |

|---|---|---|---|

| Fe2O3 % ≤: | 0.5-1.2 | Bulk Density≥ G/cm3: | 2.5-2.95 |

| A.P. % ≤: | 16-17 |

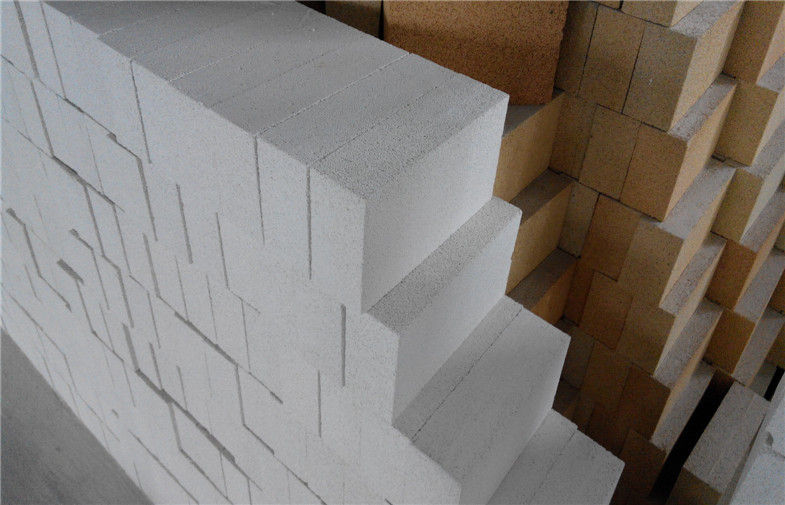

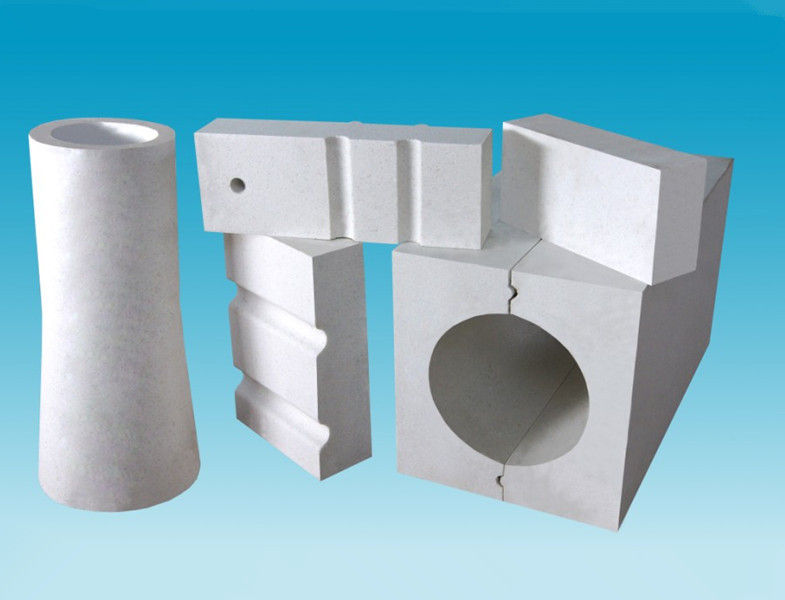

High Alumina Corundum Mullite Insulation Refractory Bricks For Glass Furnance

Quick Detail:

1, Low permanent linear change on reheating

2, Good Thermal Shock Stability

3, High dense structure

Description:

Mullite brick IS characterized by good high temperature resistance and good thermal shock resistance, whick comes into being mullite through calcine with clay, high alumina materials and ceramics.

Applications:

1, Sulfuric cracking furnace

2, Fibrous glass furnance.

Specifications:

General index of this brick,

|

Product |

Corundum and Mullite Products |

|||

|

MS-70 |

MS-72 |

MS-75 |

GM-85 |

|

|

AL2O3 % ≥ |

70 |

72 |

75 |

85 |

|

SiO2 % ≤ |

26 |

25 |

23 |

13 |

|

Fe2O3 % ≤ |

1.2 |

0.5 |

0.5 |

0.5 |

|

Bulk Density≥ g/cm3 |

2.50 |

2.65 |

2.69 |

2.95 |

|

A.P. % ≤ |

16 |

17 |

17 |

17 |

|

C.C.S (Mpa) ≥ |

70 |

80 |

80 |

80 |

|

Reheating Linear Change% |

1500°C×3h |

1400°C×2h |

1500×3h |

|

|

0.2mpa Refractoriness under loadT0.6 ≥ °C |

1580 |

1650 |

1680 |

1700 |

Competitive Advantage:

- Competitive Price. Make the products competitive in your market.

- Abundant Experience. Prevent cracks and twist in bricks.

- Different Moulds. Save mould fees for you.

- Strict Quality Control. Meet clients’ quality requirement.

- Large stocks. Guarantee prompt delivery.

- Professional Packing. Avoid damage and secure the goods in transportation