-

Parameters

-

Comments

| SiO2 %: | ≥95 | Fe2O3 %: | ≤1.0 |

|---|---|---|---|

| Refractoriness °C: | 1710 |

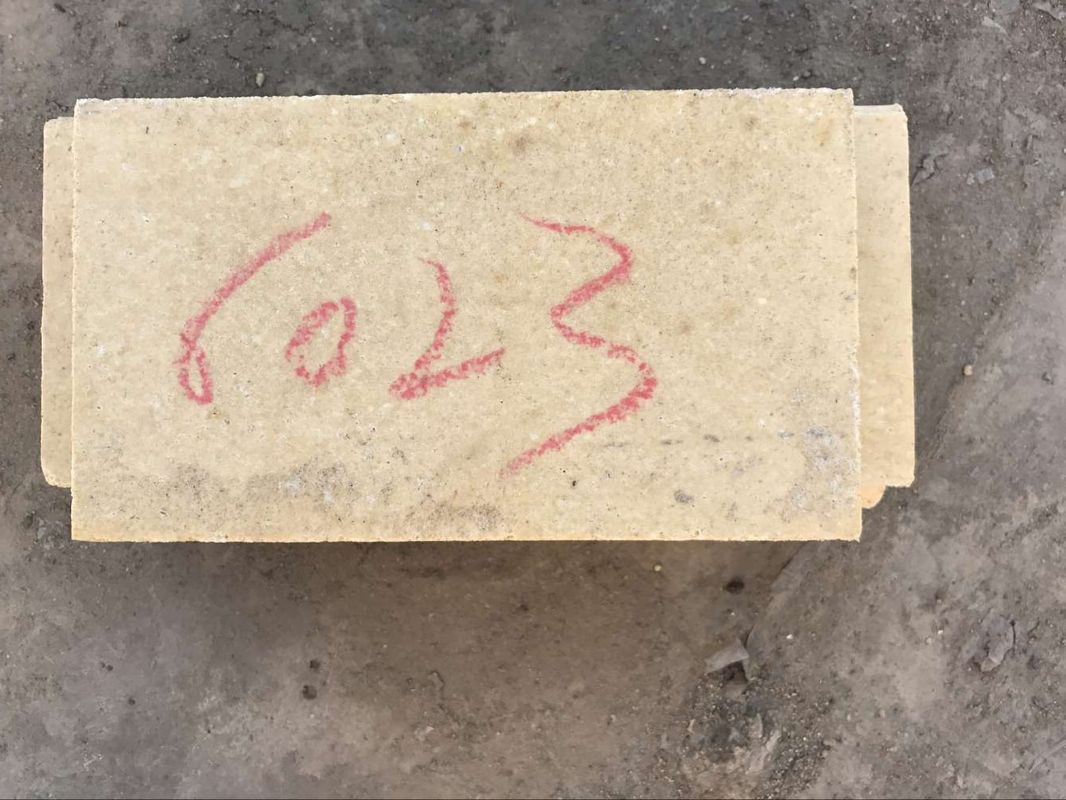

High quality silica brick is made of silicon raw material, the content of SiO2 is above 95%. And the content of Al2O3 is below 1.0%. Our factory produces various kinds of refractory products. The products can be made according with the customers' requirement.

Silica Brick Advantage:

1) Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point with temperature.

4) No shrink in burn repeatedly.

5) Temperature of refractoriness under load is above 1650º C

Stable Capability, High Quality, Excellent Service, Competitive price is the most important advantage of our products.

Silica brick advantage:

The silica brick for coke oven has low alkali and low content of residual quartz.

The silica brick has high strength and refractoriness under load.

The silica brick also has strong ability in acid slag resistance.

This silica brick is used to the walls, hearth or other parts of the combustion chamber, and carbonization chamber

Application of silica brick:

They are widely used for hot blast furnace, coke oven, and glass furnace. The products can be made according to customers' requirement.

Silica Bricks specification:

| Item | Coke Oven Silica Brick | Glass Furnace Silica Brick | Hot Blast Stove Silica Brick | |

| JJG-94 | JBG-95 | JBG-96 | JRG-95 | |

| SiO2 % | 94.5 | ≥95 | ≥96 | 95 |

| Fe2O3 % | 1.5 | ≤1.0 | ≤1.0 | 1.3 |

| CaO % | 2.5 | 2.2 | 2.2 | |

| Refractoriness °C | 1710 | 1710 | 1710 | 1710 |

| Refractoriness under load T1,°C | 1650 | 1650 | 1660 | 1650 |

| Apparent porosity % | 22(24) | 22(24) | 22(24) | 22(24) |

| Cold crushing strength Mpa | 40(35) | 35(30) | 35(30) | 35(30) |

| True Density g/cm3 | 2.33 | 2.32 | 2.33 | 2.34 |

| Thermal Expansion % |

1000°C 1.28(1.30) |

1000°C ≤1.25 |

1000°C ≤1.25 |

1000°C 1.26 |

| Residual Quartz % | 1.0 | 1.0 | 1.0 | 1.0 |