-

Parameters

-

Comments

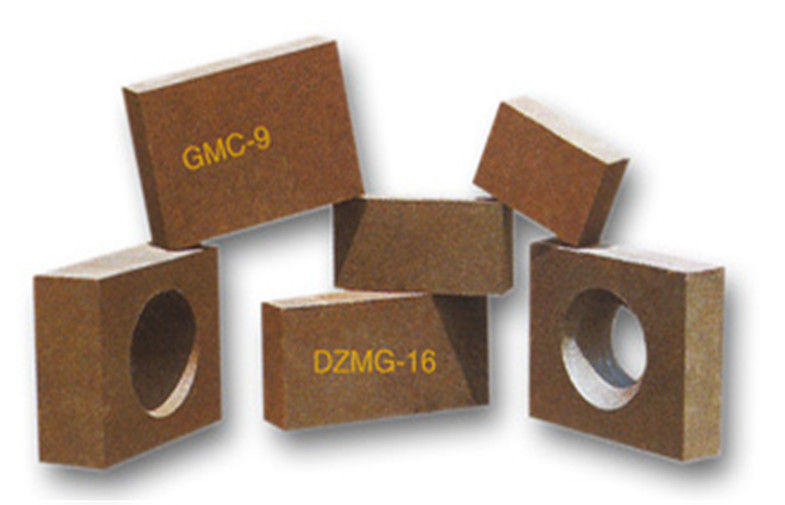

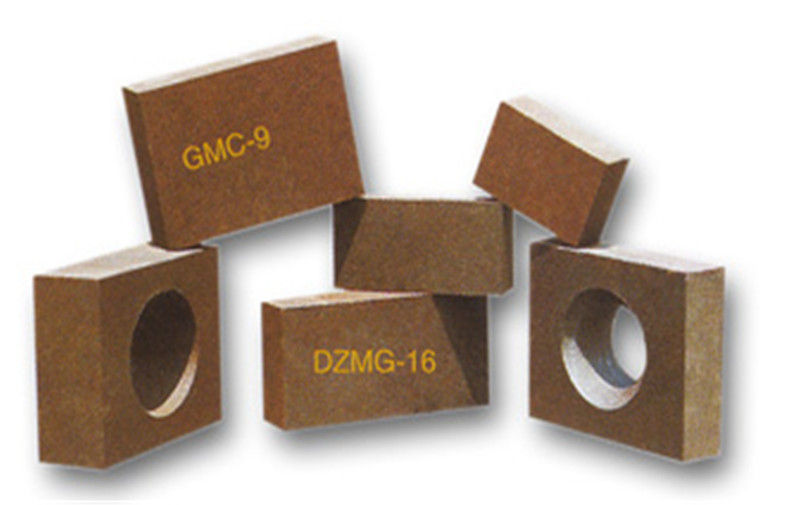

Heat Resistant Sintered Magnesia Chrome Brick Refractory For Building Materials

Quick Detail:

♦ High strength

♦ Corrosion resistance

♦ Erosion resistance

♦ Excellent slag resistance

♦ Good thermal shock stability

Description:

It is made with sintered magnesia and refractory level chrome ore as raw materials. The space between refractory grains is bonded with silicate. The domestic so called magnesia –Chrome bricks .

The refractoriness of magnesia chrome bricks are more than 2000℃,and the refractory under load is a above 1550℃.Good steady volume in high temperature , the performance of meeting sudden cold and sudden hot is better than magnesia bricks

Specifications:

Direct-Bonded Magnesia-Chrome Brick

Main Application:It’s mainly applied to line the sintering zone of the new dry-processing of cement kilns and glass tank furnaces as checkers and the other industrial furnaces.

Chemical & Physical Data

|

Brand |

MgO % |

Cr2O3 % |

SiO2 % |

A.P. % |

BDg/cm3 |

CCS.MPa |

R.U.L ℃ |

|

DBMGe-8A |

≥74 |

≥8 |

≤1.5 |

≤18 |

2.98 |

≥40 |

1660 |

|

DBMGe-8B |

≥74 |

≥8 |

≤2.0 |

≤18 |

2.98 |

≥35 |

1600 |

|

DBMGe-12A |

≥66 |

≥12 |

≤1.5 |

≤18 |

3.1 |

≥40 |

1660 |

|

DBMGe-12B |

≥66 |

≥12 |

≤2.0 |

≤18 |

3.1 |

≥35 |

1600 |

|

DBMGe-16A |

≥60 |

≥16 |

≤1.5 |

≤18 |

3.15 |

≥40 |

1660 |

|

DBMGe-16B |

≥60 |

≥16 |

≤2.0 |

≤18 |

3.15 |

≥35 |

1600 |

Rebonded Magnesia-Chrome Brick

Main Application:It’s suitable for lining of the slag zone area of refining furnaces of VOD,SKF.

Chemical & Physical Data

|

Brand |

MgO % |

Cr2O3 % |

SiO2 % |

A.P. % |

BDg/cm3 |

CCS.MPa |

R.U.L ℃ |

|

RBMG-16A |

≥65 |

≥16 |

≤1.2 |

≤16 |

3.1 |

≥45 |

1750 |

|

RBMG-16B |

≥60 |

≥16 |

≤1.6 |

≤16 |

3.1 |

≥40 |

1700 |

|

RBMG-20A |

≥60 |

≥20 |

≤1.2 |

≤16 |

3.15 |

≥45 |

1750 |

|

RBMG-20B |

≥60 |

≥20 |

≤1.2 |

≤16 |

3.15 |

≥40 |

1700 |

Semi-Rebonded Magnesia-Chrome Brick

Main Application:It’s widely used for every industrial furnaces of the metallurgical and building materials industry.

Chemical & Physical Data

|

Brand |

MgO % |

Cr2O3 % |

SiO2 % |

A.P. % |

BDg/cm3 |

CCS.MPa |

R.U.L ℃ |

|

SBMG-16A |

≥60 |

≥16 |

≤1.5 |

≤17 |

3.1 |

≥40 |

1750 |

|

SBMG-16B |

≥60 |

≥16 |

≤1.8 |

≤17 |

3.1 |

≥35 |

1700 |

|

SBMG-20A |

≥55 |

≥20 |

≤1.5 |

≤17 |

3.15 |

≥40 |

1750 |

|

SBMG-20B |

≥55 |

≥20 |

≤1.8 |

≤17 |

3.15 |

≥35 |

1700 |

Competitive Advantage:

- Competitive Price. Make the products competitive in your market.

- Abundant Experience. Prevent cracks and twist in bricks.

- Different Moulds. Save mould fees for you.

- Strict Quality Control. Meet clients’ quality requirement.

- Large stocks. Guarantee prompt delivery.

- Professional Packing. Avoid damage and secure the goods in transportation