Industrial Cast Big Mullite Brick Thermal Conductivity High Alumina Refractory Bricks

-

Parameters

-

Comments

Industrial Cast Big Mullite Brick Thermal Conductivity High Alumina Refractory Bricks

Quick Detail:

1, Low permanent linear change on reheating

2, Good Thermal Shock Stability

3, High dense structure

Description:

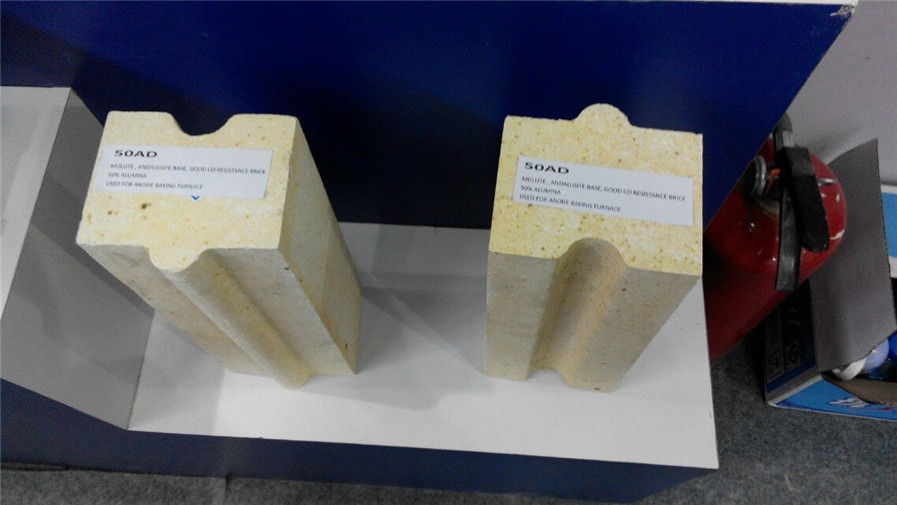

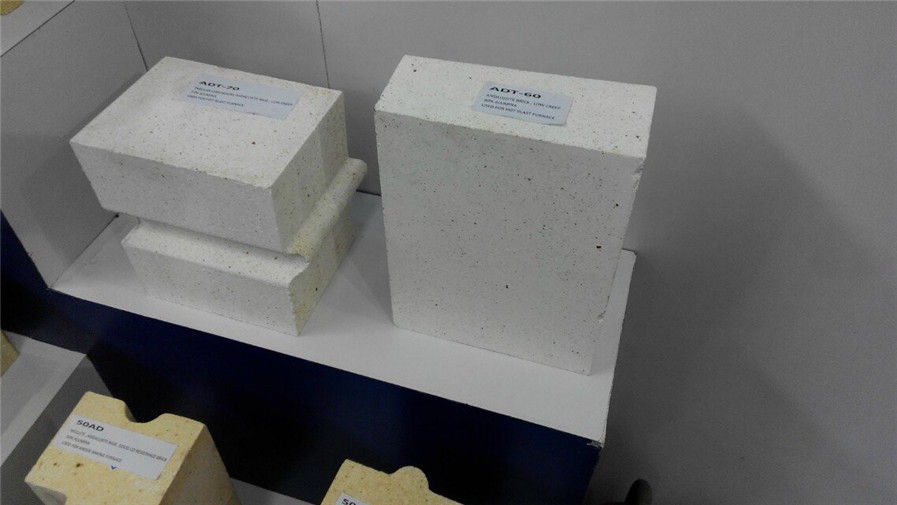

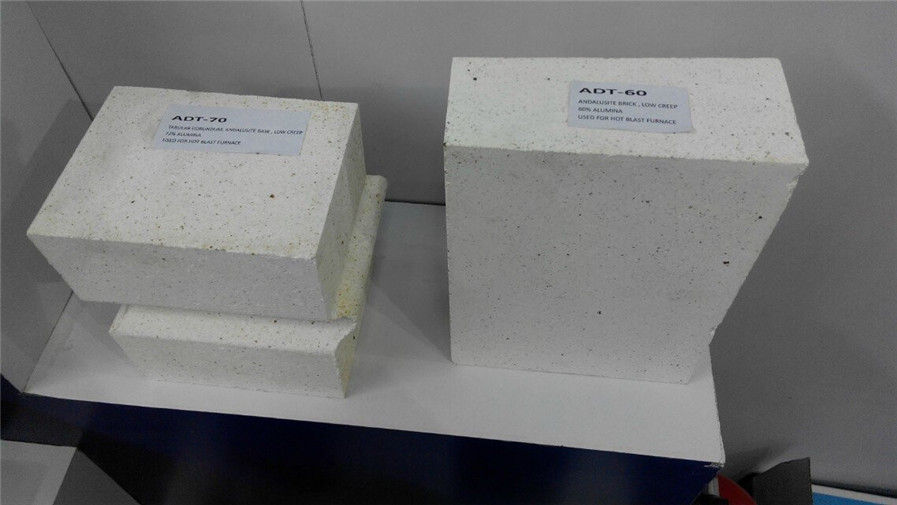

Mullite brick IS characterized by good high temperature resistance and good thermal shock resistance, whick comes into being mullite through calcine with clay, high alumina materials and ceramics.

Applications:

1, Sulfuric cracking furnace

2, Fibrous glass furnance

Specifications:

|

Item |

MU 60 |

MU 65 |

MU 70 |

MU 75 |

|

|

Chemical composition |

Al2O3 |

≥60 |

≥65 |

≥70 |

≥75 |

|

SiO2 |

≤35 |

≤33 |

≤26 |

≤24 |

|

|

Fe2O3 |

≤1.0 |

≤1.0 |

≤0.6 |

≤0.4 |

|

|

Apparent Porosity% |

≤17 |

≤17 |

≤17 |

≤18 |

|

|

Bulk Density g/cm3 |

≥2.55 |

≥2.55 |

≥2.55 |

≥2.55 |

|

|

Cold Crushing Strength Mpa |

≥60 |

≥60 |

≥80 |

≥80 |

|

|

0.2Mpa Refractoriness Under Load T0.6 ℃ |

≥1580 |

≥1600 |

≥1600 |

≥1650 |

|

|

Permanent Linear Change On Reheating (%)1500℃X2h |

0~+0.4 |

0~+0.4 |

0~+0.4 |

0~+0.4 |

|

|

Thermal Shock Resistances 100℃ water cycles |

≥18 |

≥18 |

≥18 |

≥18 |

|

|

20-1000℃ Thermal Expansich10-6/℃ |

0.6 |

0.6 |

0.6 |

0.55 |

|

|

Thermal Conductivity (W/MK) 1000℃ |

1.74 |

1.84 |

1.95 |

1.95 |

|

Competitive Advantage:

- Competitive Price. Make the products competitive in your market.

- Abundant Experience. Prevent cracks and twist in bricks.

- Different Moulds. Save mould fees for you.

- Strict Quality Control. Meet clients’ quality requirement.

- Large stocks. Guarantee prompt delivery.

- Professional Packing. Avoid damage and secure the goods in transportation