-

Parameters

-

Comments

Types Of Refractory Bricks Mullite-Sillimanite Brick For The Key Parts Of The Furnace

Quick Detail:

1. good refractory properties;

2. good stability against thermal shocking;

3. use high quality raw material;

Description:

Mullite-Sillimanite bricks are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chemical demands.

Applications:

Mullite-Sillimanite bricks primarily used for the key parts of the furnace of glass furnace, alkali-free glass fiber furnace, blast furnace hot blast stove, refractory-material tunnel kiln, etc.

Specifications:

Physical and chemical index:

| Item | LSM-75 | LSM-70 | LS-65 | LS-60 |

| Al2O3 % ≥ | 75 | 70 | 65 | 60 |

| SiO2 % ≤ | 23 | 25 | 32 | 37 |

| Fe2O3 % ≤ | 0.4 | 0.4 | 0.5 | 1 |

| Bulk density g/cm3 ≥ | 2.7 | 2.6 | 2.5 | 2.3 |

| Apparent porosity % ≤ | 18 | 18 | 18 | 19 |

| Cold crushing strength MPa ≥ | 100 | 100 | 80 | 80 |

| Refractoriness under load °C (0.2MPa,0.6%)≥ | 1680 | 1680 | 1650 | 1600 |

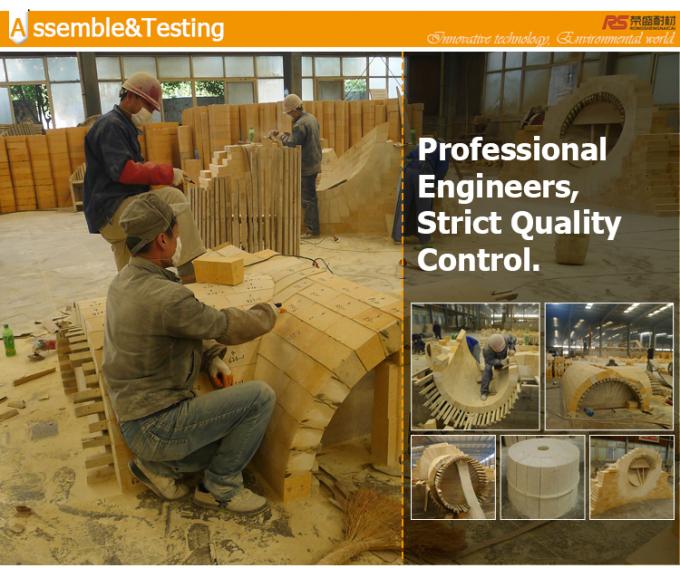

Competitive Advantage:

- Competitive Price. Make the products competitive in your market.

- Abundant Experience. Prevent cracks and twist in bricks.

- Different Moulds. Save mould fees for you.

- Strict Quality Control. Meet clients’ quality requirement.

- Large stocks. Guarantee prompt delivery.

- Professional Packing. Avoid damage and secure the goods in transportation