-

Parameters

-

Comments

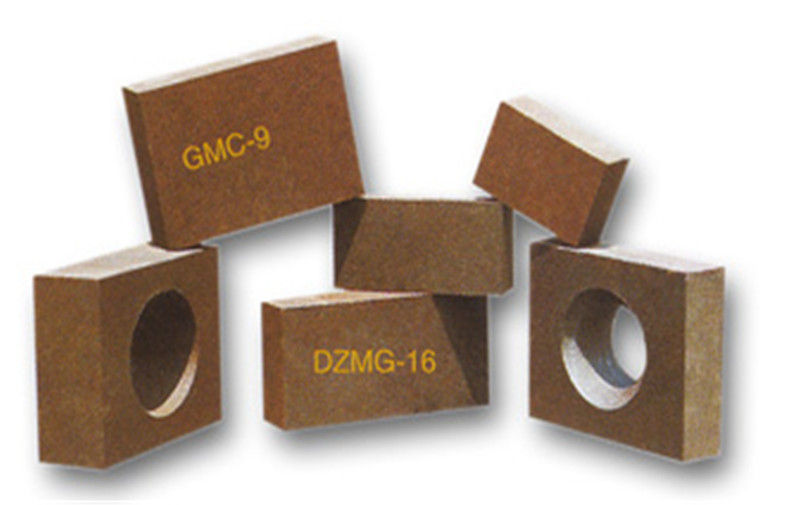

Industrial Rotary Kiln Refractory Bricks Direct Bonded Magnesia Chrome Brick

Quick Detail:

♦ High strength

♦ Corrosion resistance

♦ Erosion resistance

♦ Excellent slag resistance

♦ Good thermal shock stability

Description:

Direct-Bonded Magnesia-Chrome Brick

Main Application:It’s mainly applied to line the sintering zone of the new dry-processing of cement kilns and glass tank furnaces as checkers and the other industrial furnaces.

Application:

It is widely used in all kinds of rotary kiln, the sleeve kiln, shaft kiln and lime kiln, etc

Chemical & Physical Data

|

Brand |

MgO % |

Cr2O3 % |

SiO2 % |

A.P. % |

BDg/cm3 |

CCS.MPa |

R.U.L ℃ |

|

DBMGe-8A |

≥74 |

≥8 |

≤1.5 |

≤18 |

2.98 |

≥40 |

1660 |

|

DBMGe-8B |

≥74 |

≥8 |

≤2.0 |

≤18 |

2.98 |

≥35 |

1600 |

|

DBMGe-12A |

≥66 |

≥12 |

≤1.5 |

≤18 |

3.1 |

≥40 |

1660 |

|

DBMGe-12B |

≥66 |

≥12 |

≤2.0 |

≤18 |

3.1 |

≥35 |

1600 |

|

DBMGe-16A |

≥60 |

≥16 |

≤1.5 |

≤18 |

3.15 |

≥40 |

1660 |

|

DBMGe-16B |

≥60 |

≥16 |

≤2.0 |

≤18 |

3.15 |

≥35 |

1600 |

Competitive Advantage:

- Competitive Price. Make the products competitive in your market.

- Abundant Experience. Prevent cracks and twist in bricks.

- Different Moulds. Save mould fees for you.

- Strict Quality Control. Meet clients’ quality requirement.

- Large stocks. Guarantee prompt delivery.

- Professional Packing. Avoid damage and secure the goods in transportation