-

Parameters

-

Comments

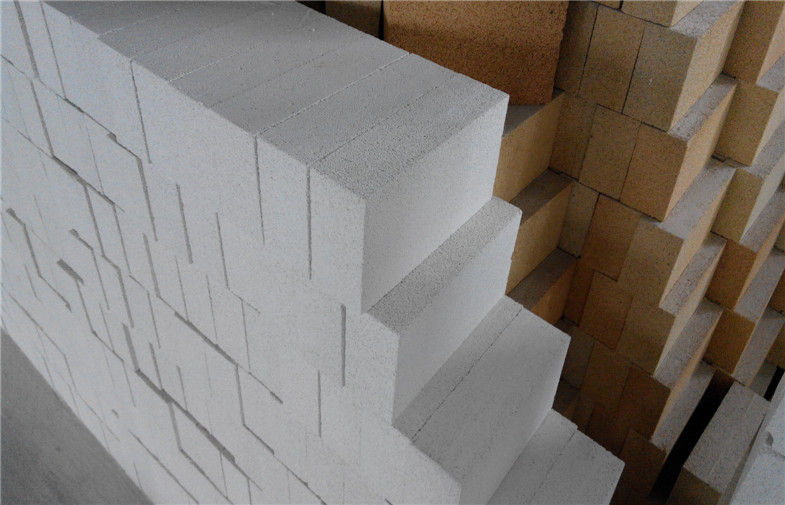

Light Weight Mullite Brick Refractory Blocks For Ceramic Metallurgy Furnace Lining

Detailed Product Description

Description:

mullite insulation bricks are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chemical demands.

Applications:

Mullite insulation bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc

Specifications:

|

Brands |

AL2O3%≥ |

FE2O3≤ |

BD G/CM3≤ |

CCS MPA≥ |

PLC ℃X H≤1.0% |

TCS W/M.K≤ |

||

|

400℃ |

600℃ |

900℃ |

||||||

|

MD-0.5 |

45 |

0.8 |

0.5 |

2 |

1350×12 |

0.18 |

0.22 |

0.26 |

|

MD-0.6 |

55 |

0.8 |

0.6 |

2.5 |

1350×12 |

0.26 |

0.3 |

0.32 |

|

MD-0.8 |

65 |

0.7 |

0.8 |

3 |

1450×12 |

0.28 |

0.32 |

0.36 |

|

MD-1.0 |

72 |

0.6 |

1 |

4 |

1450×12 |

0.3 |

0.35 |

0.4 |

Competitive Advantage:

- Competitive Price. Make the products competitive in your market.

- Abundant Experience. Prevent cracks and twist in bricks.

- Different Moulds. Save mould fees for you.

- Strict Quality Control. Meet clients’ quality requirement.

- Large stocks. Guarantee prompt delivery.

- Professional Packing. Avoid damage and secure the goods in transportation