-

Parameters

-

Comments

| MgO: | ≥80% | AL2O3: | 5-10% |

|---|---|---|---|

| Apparent Porosity: | ≤18% | Cold Crushing Strength: | ≥40MPa |

| 0.2MPa Refractoriness Under Load: | ≥1600℃ | Thermal Shock Resistance 1100℃: | 3 |

| Name: | Kiln Refractory Bricks |

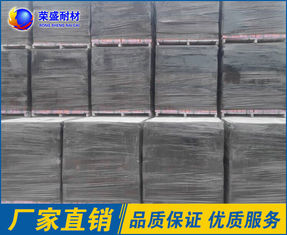

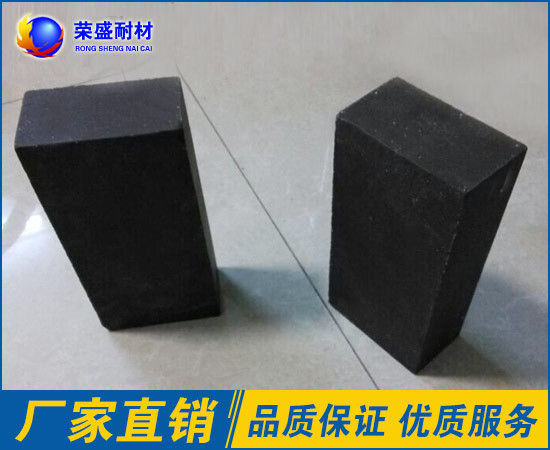

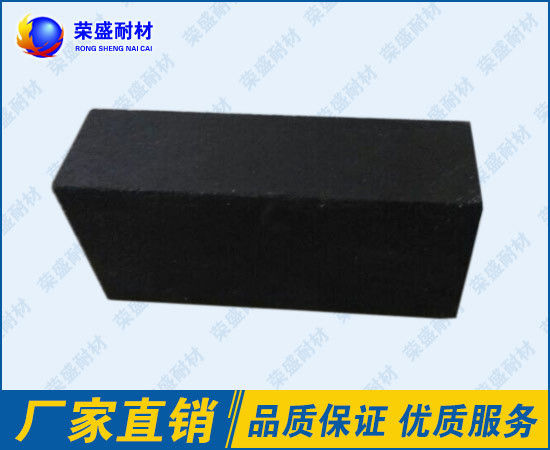

Magnesium Aluminum Refractory Fire Bricks , Industrial Furnace Refractory Bricks

Description:

Mainly used for steel-making basic open hearth and electric furnace bottom and furnace wall, the permanent lining of oxygen converter, non-ferrous metal smelting furnace, high temperature tunnel kiln, calcined magnesite brick and cement rotary kiln lining, furnace bottom and furnace wall, glass kiln regenerator checker brick, etc.

Features:

1. High temperture resistance

2. corrosion resistance

3. High degree of refractoriness,

4. good resistance to alkaline slag,

5. high temperature of load .

6. low thermal shock resistance.

Composition:

Sintered magnesite brick is made of brick and magnesia brick as raw material, after crushing, batching, mixing, molding In 1550 ~ 1600 ℃ high temperature firing, high purity products sintering temperature above 1750 ℃. No magnesia brick is added to the magnesium sand to add proper chemical binding agent, through mixing, molding, drying.

Physical and chemical index:

| Items | ML-80A | |

| MgO% | 80 | |

| AL2O3% | 5-10 | |

| Apparent Porosity% | 18 | |

| Cold Crushing Strength MPa | 40 | |

| 0.2MPa Refractoriness Under Load ℃ | 1600 | |

| Thermal Shock Resistance | 3 |

Products: